Research Vision of CRML

Building

computational

innovation to drive the physical intelligence of manufacturing and robotics systems.

Building

computational

innovation to drive the physical intelligence of manufacturing and robotics systems.

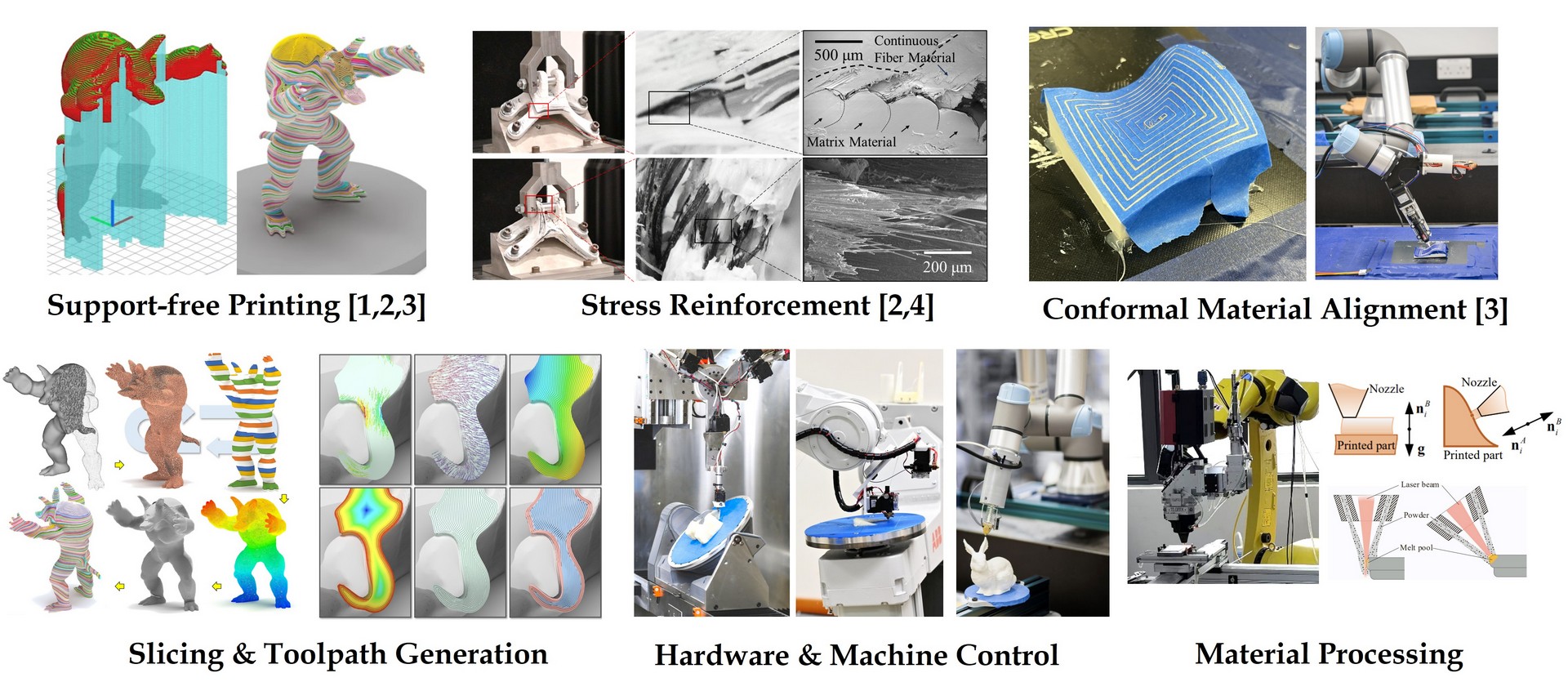

Multi-axis additive manufacturing (MAAM) has garnered significant attention for addressing the limitations of traditional planar-based 3D printing solutions, which rely on fixed nozzle orientations. By dynamically adjusting the printing direction using high degrees-of-freedom setups - e.g., robot arm, MAAM enables advanced capabilities such as support-free printing, improved surface quality, and precise control over anisotropic material properties. Our research in MAAM focuses on the key areas:

(1) Development of scalable computational for curved-based slicing and spatial toolpath generation.

(2) Collision-Free Motion Planning for multi-robot MAAM systems.

(3) Integration of functional materials to fabricate functional devices.

Selected Publication:

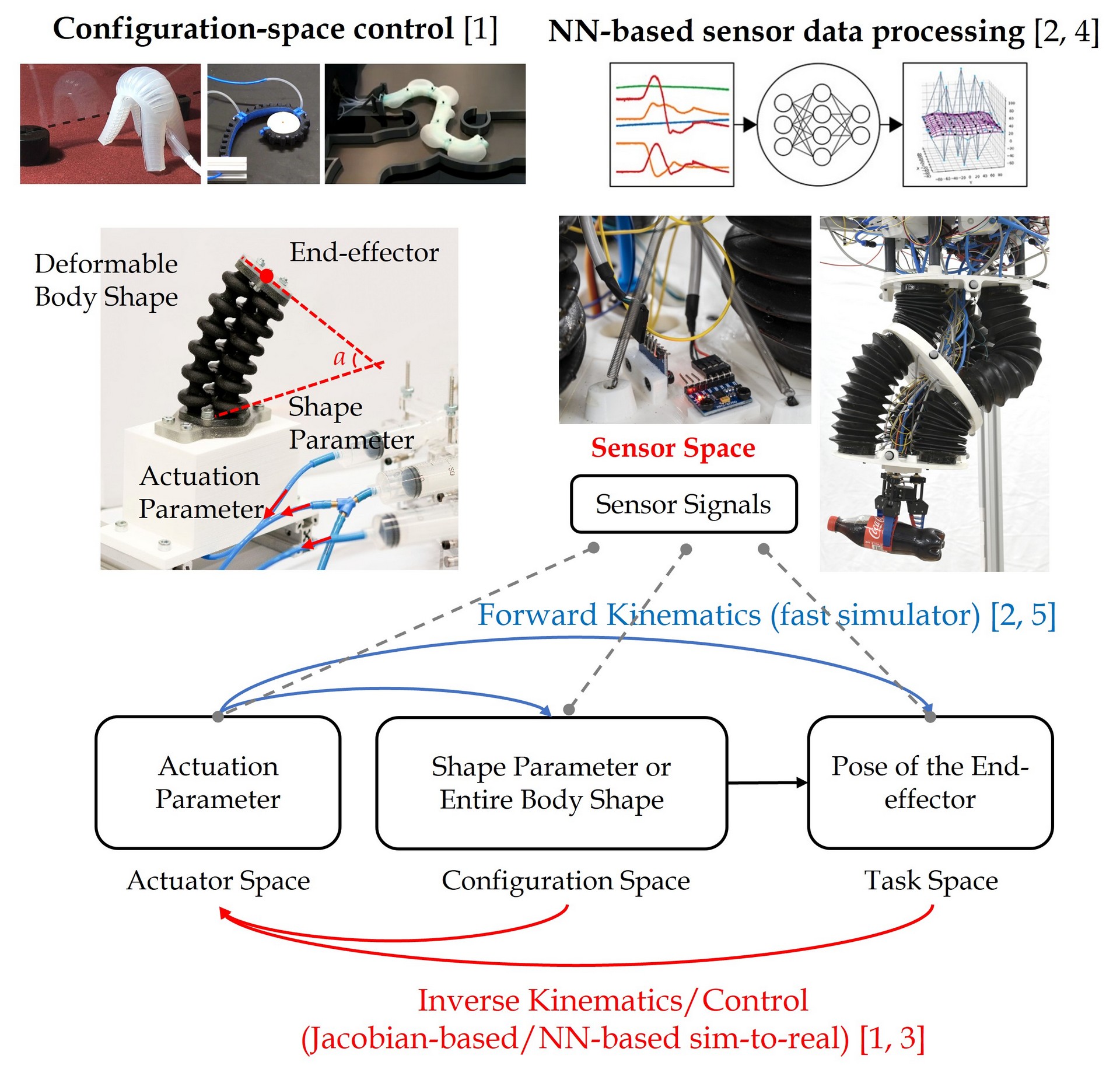

Soft robots exhibit remarkable adaptability to their

surroundings and ensure safe human interaction, and the importance of

computational tools in soft robotics research is well-recognized. We encompassing the research in rapid prototyping (by 3D printing), kinematics computation, automated design, and sensor-based proprioception in soft robots.

Selected Publication:

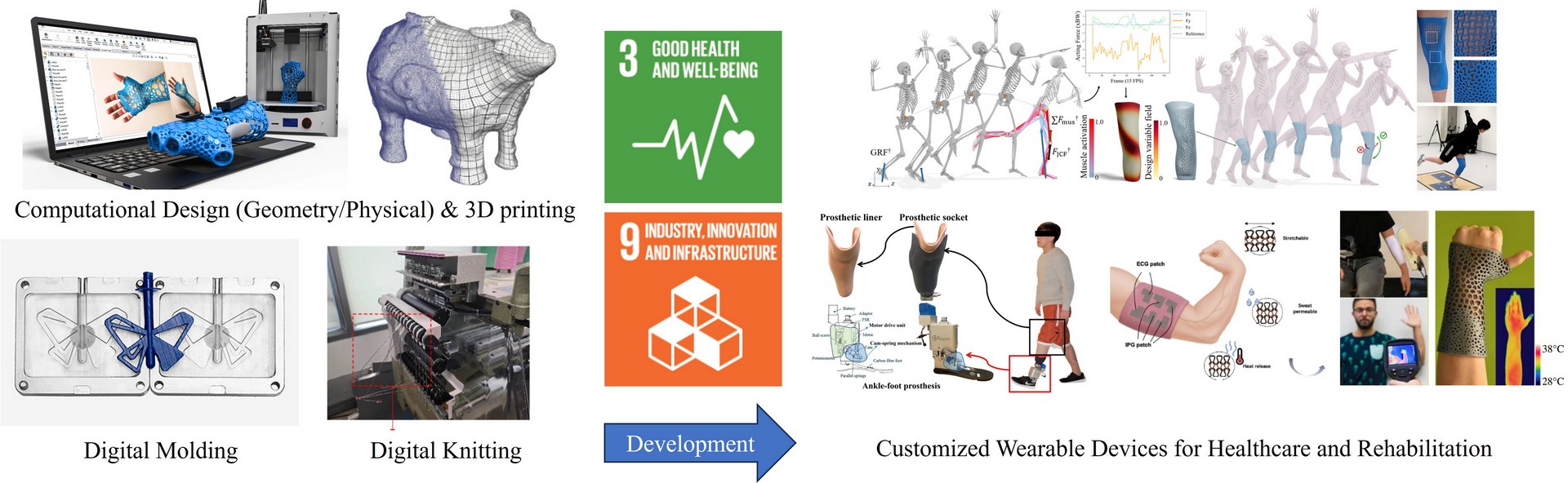

Personalized, high-performance systems tailored to individual anatomy and function have become increasingly feasible. By leveraging advanced modeling tools and data-driven design workflows, we enable the precise adaptation of devices—such as prostheses, exoskeletons, and health-monitoring wearables—to users’ unique physiological and ergonomic needs. Our research on wearable devices focuses on computational design and digital fabrication to enable customized, functional solutions. Through the seamless integration of computational intelligence and fabrication technologies, our approach advances the next generation of functional, comfortable, and accessible wearable systems that enhance quality of life and human–robot interaction.

Selected Publication: