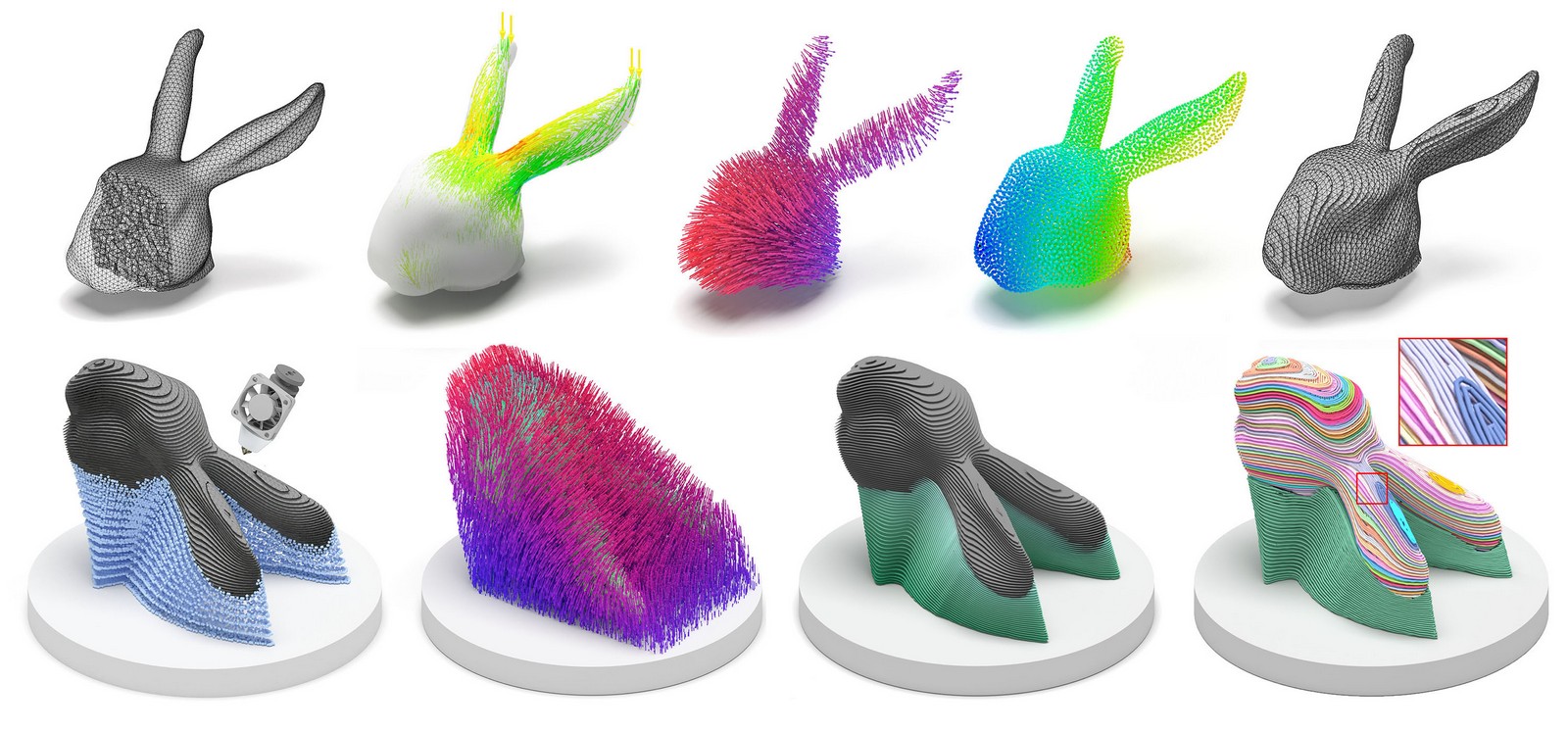

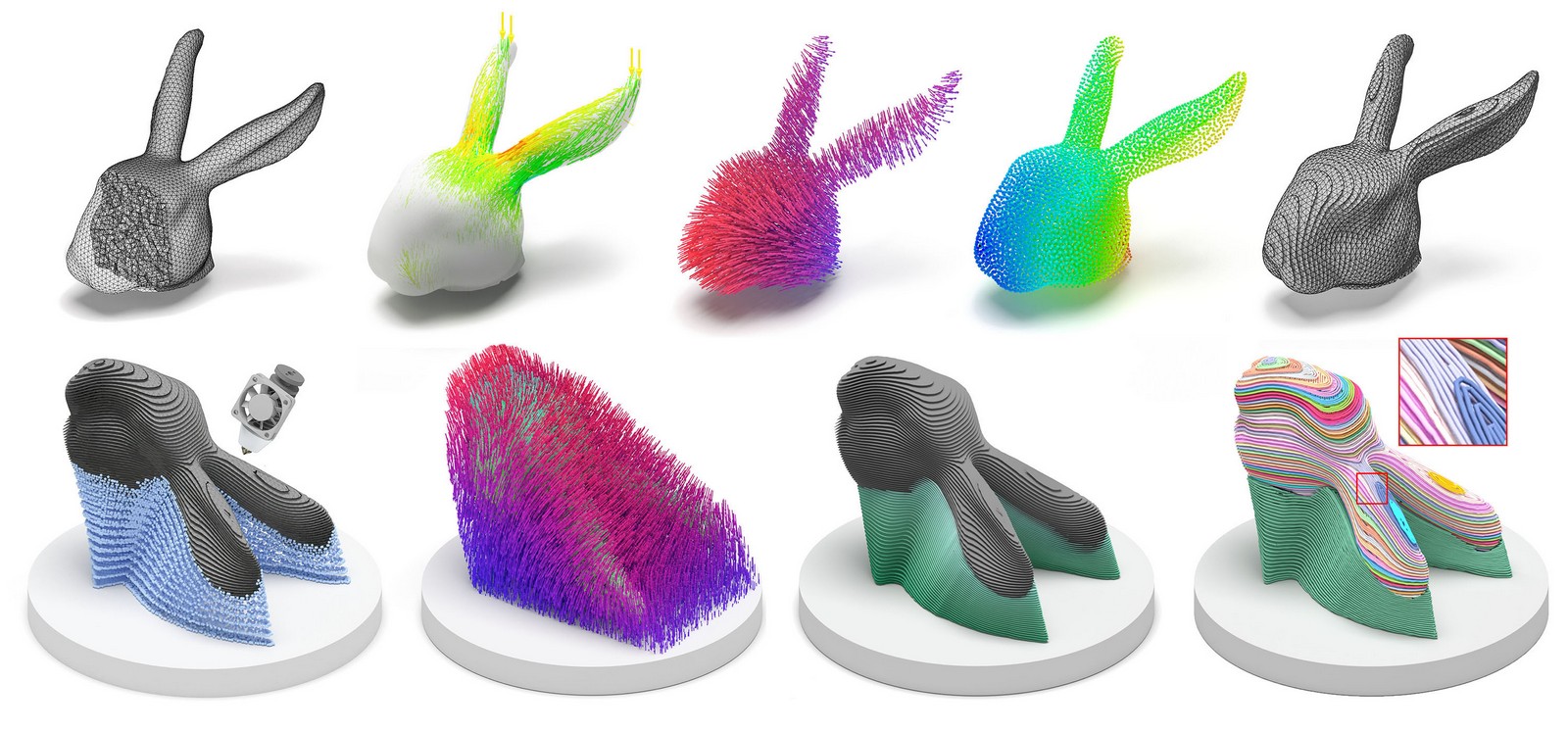

An overview of our computational framework for generating curved layers and toolpaths with controlled anisotropic strength. Our method contains two parts: 1) computing optimized field for curved layer slicing 2) farbirication enabling.

The anisotropy of mechanical strength on a 3D printed model can be controlled in a multi-axis 3D printing system as materials can be accumulated along dynamically varied directions. In this paper, we present a new computational framework to generate specially designed layers and toolpaths of multi-axis 3D printing for strengthening a model by aligning filaments along the directions with large stresses. The major challenge comes from how to effectively decompose a solid into a sequence of strength-aware and collision-free working surfaces. We formulate it as a problem to compute an optimized governing field together with a selected orientation of fabrication setup. Iso-surfaces of the governing field are extracted as working surface layers for filament alignment. Supporting structures in curved layers are constructed by extrapolating the governing field to enable the fabrication of overhangs. Compared with planar-layer based Fused Deposition Modeling (FDM) technology, models fabricated by our method can withstand up to 6.35x loads in experimental tests.

An overview of our computational framework for generating curved layers and toolpaths with controlled anisotropic strength. Our method contains two parts: 1) computing optimized field for curved layer slicing 2) farbirication enabling.

Contact information:

Guoxin Fang (g.fang-1@tudelft.nl)

Charlie C.L. Wang (changling.wang@manchester.ac.uk)